HBRVS-187.5 Digital Display Brinell Rockwell Vickers Universal Hardness Tester

NO:Brinell 187.5kgf, Rockwell 150kgf, Vickers 100kgfWe"re here to help:

Easy ways to get the answers you need. Send E-mail WhatsAPP/Wechat

+86-15254140530

Easy ways to get the answers you need. Send E-mail WhatsAPP/Wechat

+86-15254140530

Product Introduction

HBRVS-187.5 Brinell, Rockwell, and Vickers hardness tester is a multi-purpose hardness tester with three test methods and 7-stage test force, meeting various hardness test requirements. The hardness tester uses the lever to add the force, friction free spindle, high force accuracy. Wide application range, easy to operate. It is a hardness tester for industrial and mining enterprises and scientific research institutes.

Application range

Test Brinell, Vickers and Rockwell hardness of ferrous metals, nonferrous metals and cemented carbides.

It has a wide range of applications and can be widely used in the determination of:

a. Brinell hardness of castings, annealed steels, normalizing steels, nonferrous metals and soft alloys.

b. Rockwell hardness of heat treatment materials such as quenching, tempering and so on.

c. Vickers hardness of nitriding layer, ceramics, thin sheet, metal sheet, electroplating layer, and micro parts.

HBRVS-187.5 Brinell, Rockwell, and Vickers hardness tester is a multi-purpose hardness tester with three test methods and 7-stage test force, meeting various hardness test requirements. The hardness tester uses the lever to add the force, friction free spindle, high force accuracy. Wide application range, easy to operate. It is a hardness tester for industrial and mining enterprises and scientific research institutes.

Application range

Test Brinell, Vickers and Rockwell hardness of ferrous metals, nonferrous metals and cemented carbides.

It has a wide range of applications and can be widely used in the determination of:

a. Brinell hardness of castings, annealed steels, normalizing steels, nonferrous metals and soft alloys.

b. Rockwell hardness of heat treatment materials such as quenching, tempering and so on.

c. Vickers hardness of nitriding layer, ceramics, thin sheet, metal sheet, electroplating layer, and micro parts.

| Test force | Rockwell: 60, 100, 150Kgf(588, 980, 1471N) Brinell: 15.625, 31.25, 62.5, 125, 187.5Kgf(153.2, 306.5, 612.9, 1226, 1839N) Vickers: 5, 10, 20, 30, 50, 100Kgf(49.03, 98.07, 196.1, 294.2, 490.3, 980.7N) |

| Scale range | Rockwell: HRA, HRB, HRC, HRD, HRF, HRG Brinell: HBW2.5/15.625 HBW2.5/31.25 HBW2.5/62.5 HBW5/125 HBW2.5/187.5 Vickers: 5, HV10, HV20, HV30, HV50, HV100 |

| Measurement range | Rockwell:20-88HRA, 20-100HRB, 20-70HRA Brinell:5-650HBW Vickers:5-3000HV |

| Magnification times for the lens | 100X, 50X. 25X |

| Max distance between indentation center to machine wall | 160mm |

| Max height of the specimen | 180 mm for Rockwell, and 165mm for Brinelll and Vickers. |

| Dimension | 550*230*780 mm |

| Power supply | Single Phase AC220V/50Hz |

| Net weight | 80KG |

- The body part is molded by casting process and has been treated for a long time. Compared with the splicing process, the shape variables of the casting one are extremely small, and it can effectively adapt to all kinds of harsh environment.

- Car paint, high grade lacquer, strong scratch resistance, still bright as new after years of use.

- Use immediately after starting up, no need mount weight.

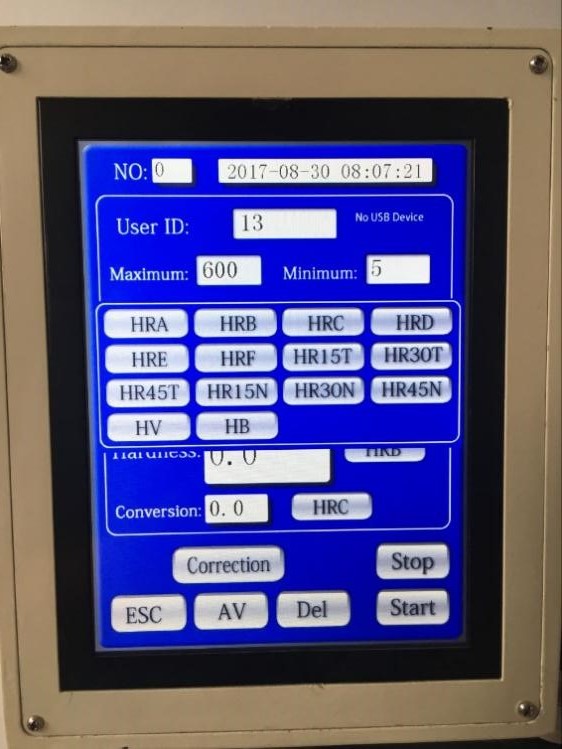

- Adopt large touch screen LCD display interface with rich contents and easy operation.

- With Brinell, Rockwell, and Vickers testing methods, 7-stage testing force, meeting various hardness test requirements.

- The hardness values of the measuring scales can be converted to each other.

- Electronic closed-Loop controls to apply the test force., and the sensor with the precision to 5‰ to control the test force, completely realize the automatic loading, dwell, and unloading operation.

- Equipped with a microscope and a high-definition optical system to make the observation readings clearer and reduce errors.

- Equipped with a built-in micro-printer, and it can realize the connecting with PC by the super-terminal through optional RS232, and output measurement reports.

Jinan Focus Test Instrument Co., Ltd.

Jinan Focus Test Instrument Co., Ltd.

Jinan City, Shandong Province, China

Jinan City, Shandong Province, China